Over the years, all eddy current brakes have been equipped with water temperature control systems at the outlets of labyrinth bulbs from various brands and sizes. One problem with these systems was that the electrical contacts would oxidize over time or the bimetallic system would lose its elastic properties. The safety measures did not intervene, and when the cooling labyrinths overheated and heated the water, this often led to deformation and frequently to the breakage of the labyrinths. To address this issue, we have developed a very efficient and precise kit for monitoring the temperature of the cooling labyrinths and used materials capable of withstanding the vibrations that can occur on a test bench.

The kit consists of:

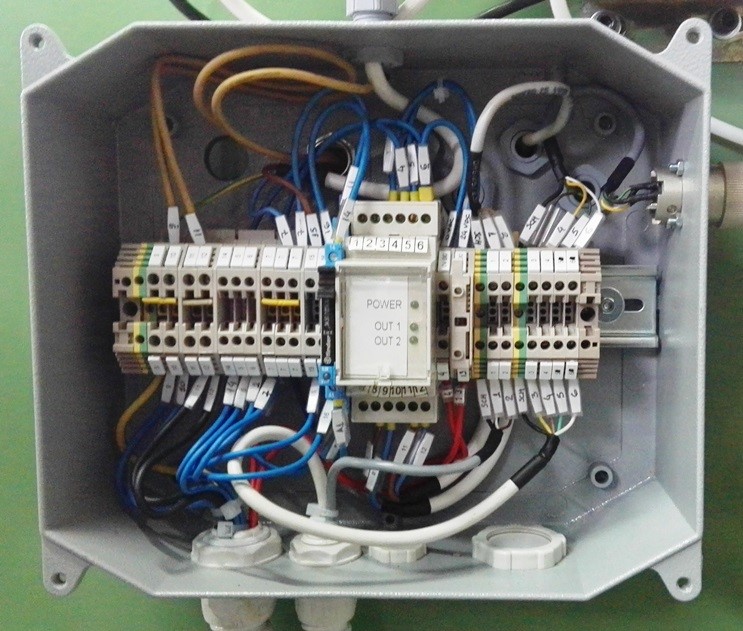

- An acquisition system in a 2U module that manages two PT100 probes and controls an auxiliary relay.

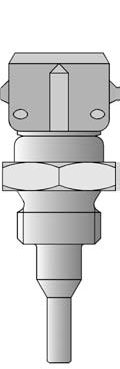

- 2 PT100 AUTOMOTIVE temperature sensors with the following technical characteristics:

- Reinforced PT100 in AUTOMOTIVE format to avoid breaks due to vibration

- Probe diameter 7.5 mm reduced to 4 mm at the end

- Thread M14 x 1.5

- Relay for PLC interface at 24 VDC complete with socket

- 2 cables with female connector, length 1.5 m

To overcome all this, we have developed this kit, which will replace any type of mounted sensor and will be housed inside the metal box located on the brake.